Dust Collectors

Wet-Dust Collector with Water Vortex System

Odor Eliminator

Oil Mist Extraction System

Fume/Gas Extractor

Arm Hood

Wet-Dust Collector with Water Vortex System

MULTISTAGE WET-DUST COLLECTOR WITH WATER VORTEX SYSTEM

DWS Series

As a wet dust collector designed to filter dust using powerful multistage water vortex, this product is effective in collecting high-temperature and ultra-fine dust and low in maintenance costs without a filter.

APPLICATION

Useful in work sites where hygroscopic, high-temperature and explosive dusts are present or generated.

Aluminum dust, Magnesium dust, Hygroscopic dust, Explosive dust, Combustible dust, High-temperature dust, High-temperature gas, Hazardous gas, etc.

FEATURES

- Ensures great filtering efficiency because dust is filtered by powerful multistage water vortex multiple times.

- Very low in maintenance costs because dust is filtered by water vortex without a filter.

- Effective in filtering special dust which cannot be handled with conventional filter-type dust collectors (e.g., sugar-containing dust, explosive dust, high-temperature dust, hazardous gas, bad smell, combustible dust, etc.)

- Ensures powerful suction, using a high-efficiency turbo fan.

- Sludge can be easily treated using a drain valve or sludge transfer pump.

- Creates power water vortex through blower suction; no separate pump to create vortex needed.

- Easy maintenance because it is able to check operations through a measuring window.

- Ensures stable filtering efficiency because an optimum water level is kept by the water level sensor in a tank.

- Able to operate and manage in a convenient fashion, using a control panel.

- Ensures normal operation even in winter with a heater in a water tank and water pipes.

- Able to eliminate bad smell with highly concentrated ozone or offensive odor-removing additives (option).

- Easy maintenance with consumable parts at the front of the product.

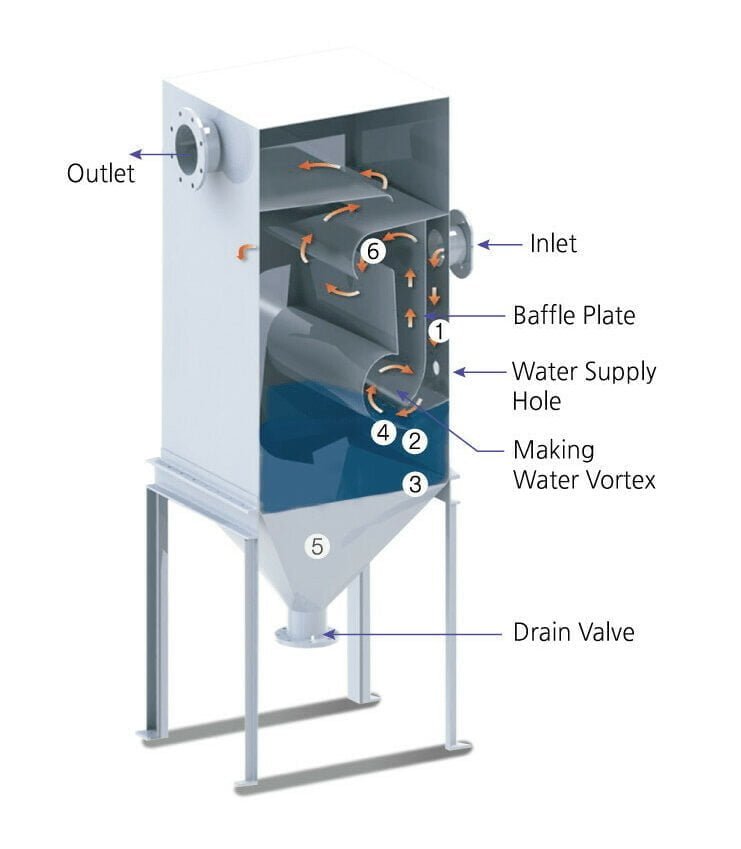

Operating mechanism of the water vortex system

- The air containing contaminants sucked by the blower hits the baffle plate (①), then passes between the ② and ③ partition, and then contacts the water in the tank.

- And then in the Slot of ④, the contaminants are separated by powerful water vortex. (in case of 2 step water vortex system, repeat this process twice.)

- And the separated contaminants become sludge and sink to the sludge tank (⑤) in the bottom of the product.

- The clean filtered air is cleaned once more by bumping against the baffle plate (⑥) while rising up, and then discharged through the outlet. If a demister filter is installed, filter the remaining contaminants and mist in the air once more.

- The sludge in the sludge tank can be handled conveniently through the automatic discharge device. (If your product does not have sludge automatic discharge device, you should clean the sludge tank frequently.)

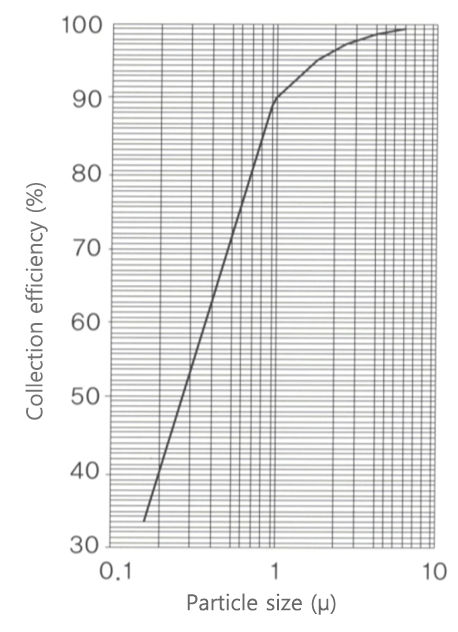

Filtering performance test results of water vortex system

- Filtering efficiency can vary depending on how well dust dissolves in water. If dust is light and water-soluble, filtering efficiency is much better.

- Filtering efficiency for non-water-soluble dust (e.g., ore, metal, etc.) is also great (see the graph).

- The upper concentration limit of dust differs depending on specific gravity, but it is nearly 20g/N㎥.

- For the treatment of high-temperature gas (150℃ or higher), it is required to attach a cooling nozzle to the inlet and lower temperature up to a certain point to have the gas sucked by the dust collector. Then, filtering efficiency tends to improve because of vapor.

사양

- Power : 220V, 380V, 440V / 3Ø / 50Hz, 60Hz

- The specifications are subject to change without prior notice for product improvement.

- Above specifications are the specifications of our standard models. We customize them to meet our clients’ needs.

CAUTION

- To collect special dust (e.g., high-temperature dust, spark, explosive dust/gas, etc.), please contact us for a consultation before placing an order.

- A stable water supply (e.g., tap water, ground water, etc.) is required.